Infrastructure Overview

Building & Storage Capacity:

Total Build-up Area: 4429 square meters (47618 square feet)

Ripening Sheds: 200 square meters (2150 square feet)

Ripening Facilities:

- Five ripening chambers with a capacity of 100 tonnes each dedicated to the ripening of fruits.

- Daily output: 100 tonnes of ripened fruit available for processing.

Dehydration/Solar Drying Facilities:

- Two dehydration/solar drying tunnels, each with a capacity of 10 tonnes.

Plant & Machinery:

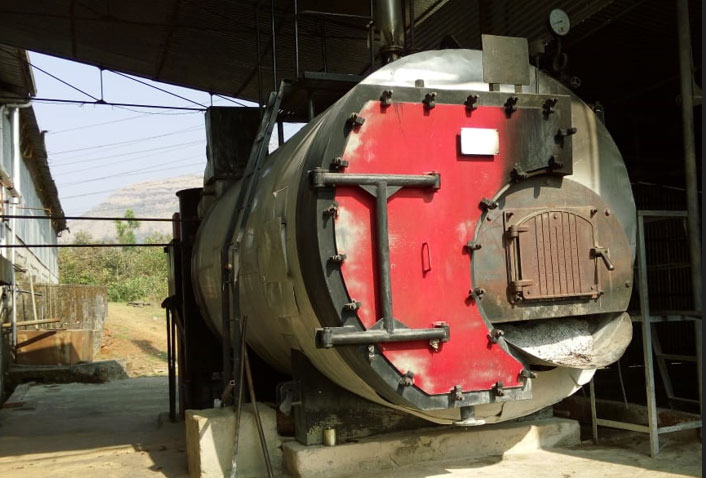

- Steam Boiler: Capacity of 3 tonnes.

- Equipment: Includes steam-jacketed kettles, pulpers (2 tonnes per hour), labeling machines, retorts, fillers, exhaust chamber, bottle sterilizers, packaging machines, PET bottle molding and blowing machines.

- Fruit Drink Production: PET bottle plant with a capacity of 10,000 bottles per shift.

- Honey Processing and Filtration Plant: Capacity of 200 kg per shift.

- Packaged Drinking Water/Alkaline Production Line: Output of 12,000 liters per shift.

- Pulping Line and Canning Line: Capacity of 5 tonnes per shift.

- Sauces, Jams and fruit spreads: 5 tonnes per shift.

- Pickles Production: Capacity of 3 tonnes per shift.

Juice Plant

Production Area

Ripening Chambers

Ro Plant

Boiller

ETP Plant